Cleanroom Services

Services

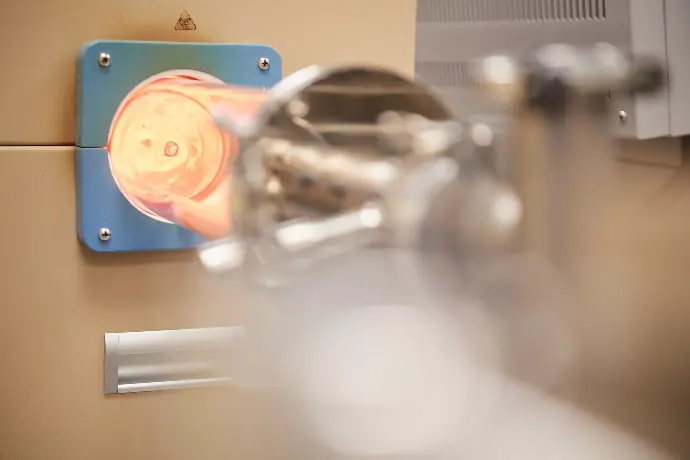

Metallization

Wet & dry etching

Photo & e-beam lithography

Laser & FIB

Sputtering & thermal deposition

PCD, PECVD, LPCVD & ALD

Back-end process & packaging

SEM, TEM, profilometry, nanoindentation

Materials

Substrates: Si, III-V, porous, quartz, ...

Metals: Al, Ag, Au, Ti, Ni, Cr, Pd, ...

Dielectrics: Si3N4, SiO2, Al2O3, TiO2, HfO2, …

Polymers

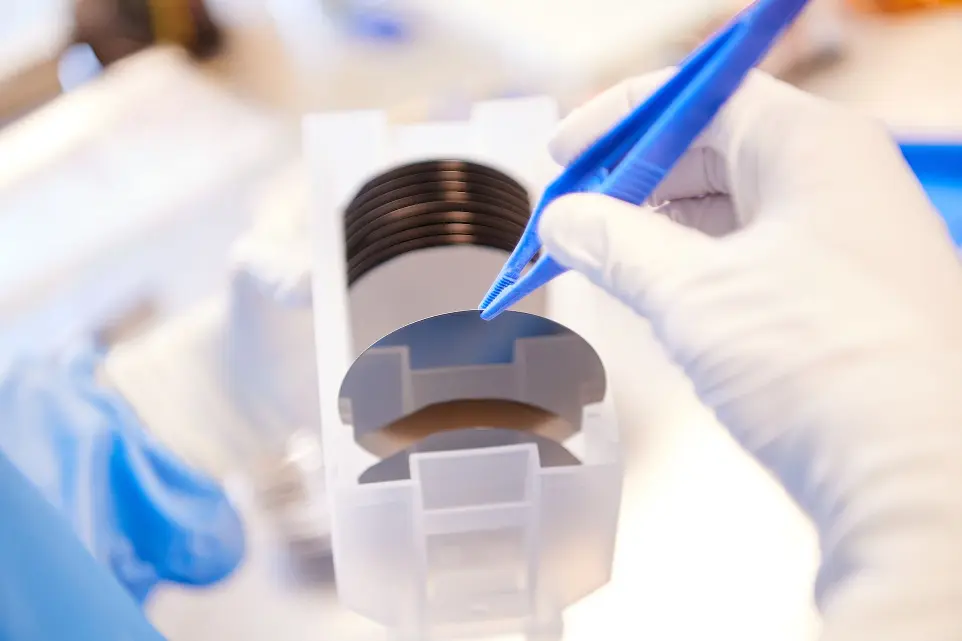

Samples

Shape: from wafer to piece of wafer

Size: from die to 8 inches

Facility

WinFAB is the cleanroom of UCLouvain and house of esteemed reputation of expertise and innovation.

Area: 1000 m²

Class: < 10 particles of100 nm/feet³ of air

Equipment: 50 advanced R&D cleanroom equipment

Tools: surface-patterning, thin films deposition and etching & back-end processes

Activities: SOI-CMOS, thin film characterization, co-integration, photovoltaic, MEMS-NEMS, sensors, bio-technologies, porous Si, organic electronics & nano-electronics

Questions?

Embark with us on a journey to build technology for future generations

Join us and make tomorrow's technology possible.